The Semiconductor Apocalypse No One Would See Coming

How a secretive mineral factory in a small town in North Carolina controls the world's ability to manufacture semiconductors.

Hey, I’m Vikram 👋 and thanks for reading! Reply to this email with your feedback. I love hearing from you. I also recommend joining other readers on Substack chat.

If you like these articles, please let others know. Word of mouth helps grow this newsletter! 🙏

It always feels like we are one natural disaster away from total planetary darkness.

In 2022, an earthquake clocking 6.8 on the Richter scale struck Taiwan, where TSMC today produces over 60% of the world’s semiconductors and 90% of the advanced technology nodes. The Chelungpu Fault in Taiwan puts most of the world’s chip supply at major risk in the event of such natural disasters.

But there are more semiconductor supply chain bottlenecks than most people realize.

Turns out the world’s semiconductor supply could also end if natural disaster were to strike a mining factory located in a small, sleepy town called Spruce Pine, North Carolina. The company that runs the factory, Unimin, was founded in 1970 and is a subsidiary of a Belgian mining conglomerate, Sibelco. What do they produce and why is this so important to semiconductors?

The Making of Semiconductor Grade Silicon

To understand why this company is important, we need to learn a little bit about how semiconductors are made. The starting material for silicon is silicon dioxide (SiO2), or quartz - an abundant material on earth in the form of sand. The naturally occurring form is not useful and the two oxygen molecules need stripped off to get pure silicon. As it turns out, separating silicon for semiconductors is no easy task due to the number of chemical processes needed to reach the required purity.

The quality of silicon needed for chips is 99.99999999999% purity. That means there cannot be any impurity atom in a billion silicon atoms. Yes, that pure. There are many chemical processes required to extract silicon of this level of purity. But when extracted, it cannot simply be used to construct chips. The silicon is used to grow silicon crystals with a definite molecular arrangement to produce defect free silicon used for semiconductor uses.

The method to grow silicon crystals was invented by Jan Czochralski. While writing on his desk one day, he accidentally dipped his pen into a bottle of molten tin instead of ink and noticed that there was a single crystal formation of tin from the edge of the pen. Side note: Who leaves molten tin lying around on a desk? Seriously. I guess we’re glad he did, because it formed the basis of producing semiconductor-grade silicon on a commercial scale.

Today the process is called the Czochralski or CZ method, and it involves melting pure silicon in a crucible at a high temperature in an environment free of contaminants. A pure seed crystal of silicon is then attached to a long rotating rod and dipped it into the molten silicon. By slowly pulling upward, pure monocrystalline silicon is formed and the result is a silicon ingot that is later sliced into thin wafers. Check out this YouTube video if you want a full explanation.

CZ Crucible and High Purity Quartz

Here’s the catch. To create this ultra pure crystalline silicon, you need to melt it in a special crucible. This crucible should both withstand the high heat of the melting process while not contaminating the highly pure melted silicon it contains. The one material capable of this is quartz. Wait. Isn’t quartz easily available from sand? No, it requires the high purity variety, a special kind only found most abundantly in …

… Spruce Pine, North Carolina.

The Unimin facility in Spruce Pine produces what they market as Iota quartz, with Iota 8 being the purest form at 99.9992% purity and valued at $10,000 per ton. For comparison, construction sand is a few dollars per ton. But why here?

As it turns out, 380 million years ago, Africa collided with Eastern America creating this special form of highly pure quartz under extreme heat in the absence of any water, fifteen miles below the surface of the earth. As a result, the world’s most precious resource for semiconductors happens to be in abundance in North Carolina, where Unimin runs its mining operation.

But mining at Spruce Pine did not begin with high purity quartz. Scientists from the Tennessee Valley Authority in late 1940s were mostly focused on the prospects of mining feldspar and mica in the region. The quartz left behind was considered a waste byproduct and used for construction sand.

Also, not all quartz produced at Spruce Pine is used for semiconductor applications. Lower quality quartz of 98% purity known as SP55 makes for beautiful, white sand traps used in golf courses such as the Augusta National Golf Club located four hours south of Spruce Pine. 4000 tons of this stuff has also been exported to golf courses in Dubai too. Even a desert country imports sand because quartz sand looks so great.

Semiconductor’s Wonka Factory

Unimin’s discovery of high purity quartz was accidental when they showed in the late 1980s that Spruce Pine deposits were of higher quality than what their competitors were producing - International Minerals and Chemicals Corporation (IMC), Indusmin Inc. and Feldspar Corporation. Unimin then took over Indusmin Inc. to avoid competition but were immediately hit with Anti-Trust litigation from the US Justice for the wrong reasons - to avoid a Feldspar monopoly. Indusmin Inc ultimately failed to compete with high quality quartz produced by Unimin and were ultimately taken over by them. This put Unimin in a rare position of monopoly over the market for high purity quartz just when the semiconductor industry was taking off.

In 1994, unforeseen issues with the water supply further reduced quartz supply and increased quartz prices. It further strengthened Unimin’s monopoly in the area because the water supply to the Spruce Pine area was reduced for two reasons:

A small group of anti-mining, pro-environment activists lobbied to save a rare, tiny species of mussel called the Appalachian Elktoe Mussel.

The Spruce Pine district was being built as a recreation area called “mineral city” that relied on neighboring water bodies for drinking water supply.

The increased regulation on the area’s water resources drove away competitors from the area leaving Unimin in the driver’s seat.

Today, Unimin is famous for being extremely secretive about its methods and operations. They do not publicize how much high purity quartz is produced from the facility each year. They have contractors sign confidentiality agreements to enter the facility and ensure that the work is spread out between different contractors, so that no one entity knows too much. They even filed a lawsuit against a mom-and-pop store owner who used to work at the facility and then joined a competitor before starting his pizza kitchen.

Due to the secretive nature of the quartz industry, it is hard to find much information online, but this blog appears to be written by someone who worked in the Spruce Pine quartz business for over 30 years. It is a difficult read but full of rare information. This YouTube video shows arial images of the quartz deposits around the Unimin factory.

Where are we today?

Crucibles for semiconductor manufacturing are heavily reliant on the supply of high quality quartz and estimates suggest that over 90% of the world’s high purity quartz comes from Spruce Pine. There are a few other suppliers such as Norwegian Crystallites in Drag, Norway, Russian Quartz in the Chelyabinsk region in Russia and Jiangsu Pacific Quartz in China. But it is unclear how much of a market share they hold on the global stage.

In 2023, Sibelco (the mining conglomerate) announced a $200 million investment to double the production of high purity quartz out of its Spruce Pine facility. The continued growth of the semiconductor industry leads to an expected $1.7 billion market for high purity quartz with a 6.5% CAGR by the end of 2032. Unimin is part of Covia Holdings Corporation since 2018.

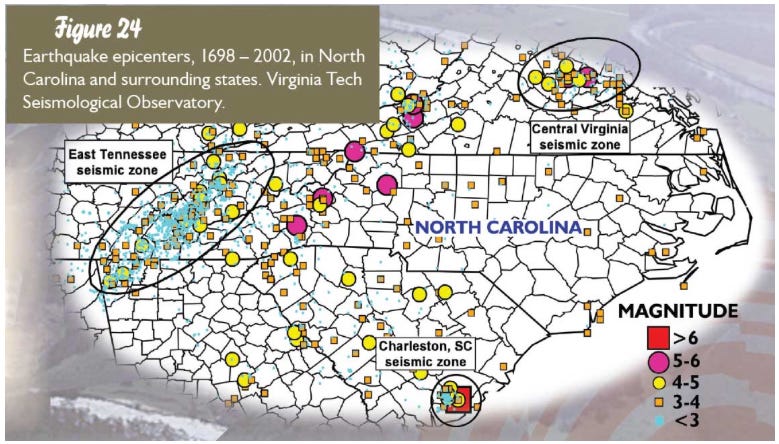

In 2008, the world’s semiconductor production skipped a heart beat when the Unimin facility caught fire. No lasting damage was done. But, if there is one thing that helps us sleep well at night, it’s knowing that North Carolina has no active faultlines that can cause earthquakes. Earthquakes are not common, and there have been no recorded destructive seismic events for a long time. Let’s hope it stays that way.

Finally, if you want to read a well written story about the history of quartz and its relevance to silicon manufacturing, check out this WIRED article.

The views, thoughts, and opinions expressed in this newsletter are solely mine; they do not reflect the views or positions of my employer or any entities I am affiliated with. The content provided is for informational purposes only and does not constitute professional or investment advice.

Damn, you called it Vik!

What do you make of the once in 1000 years flood that Spruce Pine was hit with as a result of hurricane Helene?