Can You Vibe Your Way Through Chip Design?

Reinforcement learning, inverse design, and the cultural shift in electronic design automation; a look at how AI is breaking design conventions in hardware engineering.

The goal of this post is simple: everybody is “vibing” everything online and I want to explore how it applies to hardware design.

Here is the structure of the article:

When “Vibes” Replace Engineering Discipline

What Does “Vibing” Look Like in Hardware Design?

Beyond Optimization: What Makes Vibe Design Different

Vibing with Inverse Design

Designs So Good They Don’t Look Human Anymore

🔒 LLMs, Agentic AI, and the Future of Circuit Design (+ other examples of autonomous hardware design)

Read time: 11 mins

When “Vibes” Replace Engineering Discipline

Since Andrej Karpathy coined the term "vibe coding" to characterize what appears to be the new paradigm of software development, the hardware engineer in me has been mildly agitated. Everyone on the internet swiftly grasped the concept, but the overall laziness in the approach has triggered me. Citing Karpathy's tweet,

I ask for the dumbest things like "decrease the padding on the sidebar by half" because I'm too lazy to find it. I "Accept All" always, I don't read the diffs anymore. When I get error messages I just copy paste them in with no comment, usually that fixes it. The code grows beyond my usual comprehension, I'd have to really read through it for a while. Sometimes the LLMs can't fix a bug so I just work around it or ask for random changes until it goes away.

If you've been busy doing real engineering and haven't heard the phrase yet, congratulations. Vibe coding is the process of building software solely using "vibes," such as asking an AI assistant what you want and having it execute it for you. You concentrate on the end result; the machine takes care of the details.

I see how this is useful, but there is an air of callousness around the term “vibe” that I don’t much care for. At the risk of sounding dated, I still believe that you must understand the underlying technical principles and cannot rely on vibing your way out of everything, especially as the scale and complexity of a problem increases. Fireship explains it way better than I can. Do watch this video.

What Does Vibe Design Look Like in Hardware?

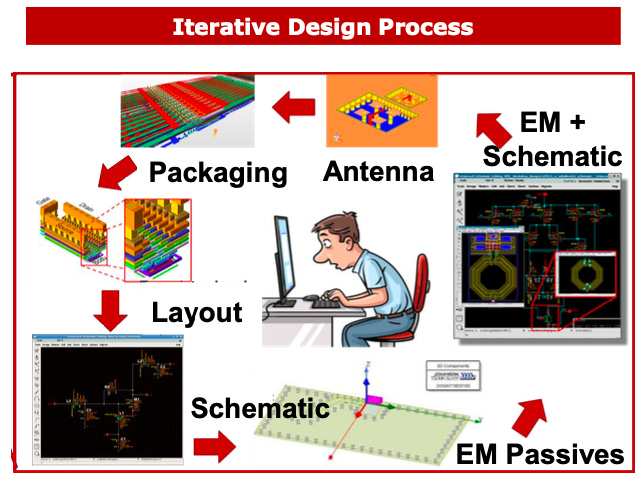

Regardless of my feelings for the word “vibe” I want to embrace the spirit of it in hardware design because it could enable a tectonic shift from how we design circuits today. In traditional circuit design, we start at a "known good" initial point and use our intuition (vibes?) to repeatedly modify and simulate the design till the desired performance is met.

I envision “vibe designing" involves making design modifications using pure language input or other similarly easy input mechanism, with the human serving as the design manager and intelligent assistants actually doing the design. Vibing eliminates all of the tedious effort associated with configuring circuits, layouts, test benches, and optimization objectives.

Human input should still be the primary factor in machine-based design. It should be possible to ask AI design a circuit from scratch or to trade off some gain for better efficiency. Or simply ask that it redesign a circuit for a different operating frequency.

The main reason this can work in electrical engineering is many subfields of electrical engineering are seemingly just orthogonal enough to develop streamlined, agentic, vibe-guided flows specific to them. In RF circuits, the design goals for a low-noise or power amplifier are different. In photonics, modulators, waveguides and metasurfaces all have different design principles. The ideal AI-enabled approach would be to incorporate machine intelligence for each application instead of a one-size-fits-all strategy.

Beyond Optimization: What Makes Vibe Design Different

You could argue that vibe design is just a hipster term for optimization. Every EDA software for electronic design includes some kind of optimization tool which relies on tuning design parameters till the specifications are met. What then is the difference?

Optimization assumes that you already know topology of the design, and that you just want to fit parameters to it. Going back to our amplifier example, optimization can find the best geometric parameters for the spiral inductor used in the matching network. Or if you are designing a wave-guiding system in photonics, you can optimize its dimensions.

Vibe design would go beyond simple optimization. Much like your design manager tells you what to do, you simply want to ask for circuit optimizations to be made using human language interface. The machine then redefines the specifications, sets up the correct simulations, and tunes the right parameters.

With the availability of massive computing power, we can utilize the power of machines to explore design spaces that would otherwise clearly lie outside the realm of conventional engineering intuition. By exploring design choices that humans would not consider viable, we open doors to unprecedented design performance.

Vibing with Inverse Design

In his seminal blog post The Bitter Lesson, computer scientist Rich Sutton explains that it is a losing proposition to teach machines to design exactly like humans do. Relying on massive compute to leverage search and learning is always the right answer when it comes to machine based approaches. We have seen this play out in the world of chess, where engines like Stockfish easily outclass the best human players in the world.

Similarly, leveraging learning and large scale search would be the way forward for many hardware engineering design problems. Of all the options available today, inverse design technique is the closest we come to vibing our way through hardware engineering. In a recent post, we looked at the use of GPU-accelerated inverse design techniques in lithography and how mask shapes in leading edge nodes seemingly break the boundaries of intuition.

Usually, engineers start with the design and tweak it till the specifications are met. Inverse design flips the flow. With a set of specifications provided, machines would use search and learning to make the best hardware design possible and outclass the most experienced hardware designers in the world.

That's the corporate dream at least.

Designs So Good They Don’t Look Human Anymore

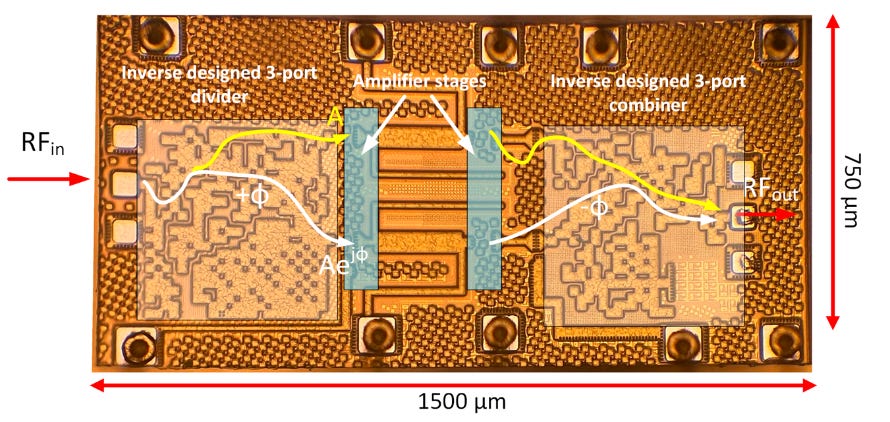

At 2025 ISSCC, Prof. Kaushik Sengupta's group at Princeton University demonstrated that they could use reinforcement learning and inverse methods to completely design a millimeter-wave power amplifier end-to-end using AI.

Based on specifications alone, they use AI to decide the amplifier architecture, circuit topology and perform parameter optimization. The final amplifier is a combination of transistors properly sized for operation, and a bunch of inverse designed matching networks that do not conform to 'templates' such as spirals or stubs. Given the required s-parameters of a generalized multiport network, inverse design tries to find the optimal physical structure of electromagnetic passive devices.

The optimal matching network design as it turns out, completely breaks human intuition, looking more like QR codes. Just look at the divider and combiner layouts in the chip photograph below. Princeton even has a nice blog article about this. In the upcoming 2025 International Microwave Symposium, these researchers have a paper that uses generative AI for electromagnetic synthesis with a crafty name — Th3F-4: Dall-EM: Generative AI with Diffusion Models for New Design Space Discovery and Target-to-Electromagnetic Structure Synthesis. I’d definitely be interested in attending this.

To be clear, the research group's approach is not a blind search for the optimal design. There would far too many degrees of freedom for that. Instead, the algorithm is trained much like a human designer with access to simulation tools.

The reinforcement learning engine and decision making agent performs simulations and observes the results. Repeated experiments with amplifier architectures, various cell topologies (like common-base, common-emitter, stacking, etc.), different parameter values, and inverse passive designs helps it build design intuition.

In their ISSCC paper, the Princeton University authors provide an example of the kind of intuition the RL algorithm can develop:

For example, it can understand that high output power is more efficiently realized with a multi-port EM combiner, as opposed to a single two-port matching network with high impedance transformation ratio. When trained effectively, it can also understand that the driver needs to be strong enough to saturate the main stage, while not being over-designed and inefficient.

This kind of intuition is often built up over years of design iteration, trial and error. With 400 CPU cores, the training cost for EM passives is about 10 days and about 2 days for RL-enabled RFIC synthesis. Post training, you can have a manufacturing ready design in a matter of minutes.

It does appear that we are entering a new world of AI-designed RFICs that are highly specialized, agentic and autonomous. Perhaps we could interact with these systems in the future with only verbal cues to design the products we need.

ML-based techniques for analog design are nothing new; check out my earlier post below on the topic. After the paywall, I’ll provide my thoughts on why it is different this time, and other examples of how streamlined agentic-AI is enabling better hardware design.